Are you curious about liquid silicone rubber mold design? In this article, I will explain the ins and outs of this innovative process. Liquid silicone rubber (LSR) molds are widely used in various industries due to their flexibility, durability, and precision. Let’s dive into the world of LSR mold design!

The Basics of Liquid Silicone Rubber Mold Design

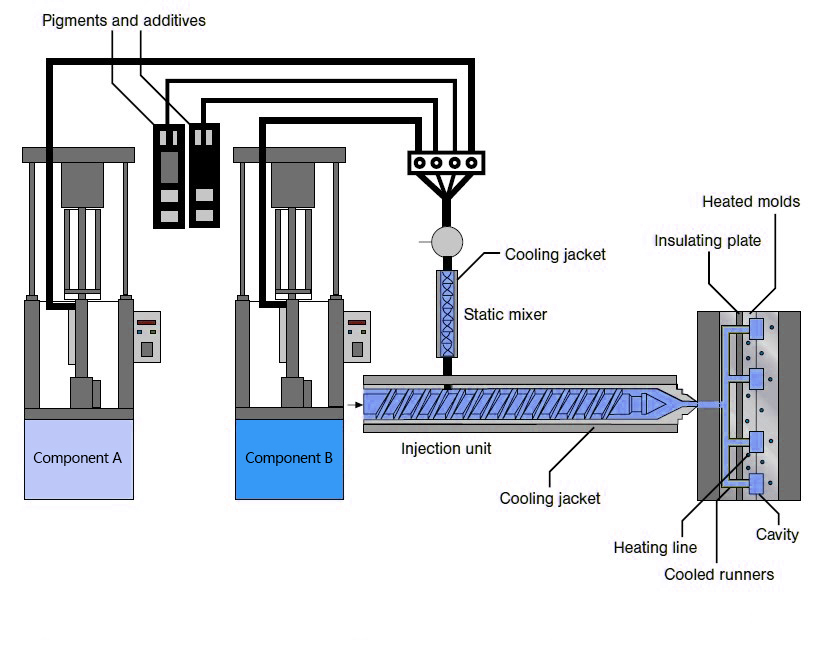

Liquid silicone rubber mold design involves creating a precise cavity that allows for the injection of liquid silicone rubber material. The mold is typically made from high-quality steel or aluminum to ensure longevity and accuracy. The design process includes considering factors such as part geometry, draft angles, gate locations, and venting systems.

By carefully designing the mold with these considerations in mind, manufacturers can achieve consistent part quality while minimizing defects like flash or air entrapment. Additionally, LSR molds can be designed with multiple cavities to increase production efficiency.

JVTECH: Revolutionizing Liquid Silicone Rubber Mold Design

One company at the forefront of liquid silicone rubber mold design is JVTECH. With years of experience and cutting-edge technology, they have revolutionized the industry by offering innovative solutions for complex molding challenges.

JVTECH utilizes advanced software tools to simulate flow behavior during injection molding processes. This enables them to optimize designs before physical production begins, reducing time-to-market and ensuring cost-effectiveness.

In addition to their expertise in simulation-based design optimization, JVTECH also offers comprehensive support throughout all stages of product development – from initial concept evaluation to final production validation.

The Role of LSR Companies in Liquid Silicone Rubber Mold Design

An essential aspect of successful liquid silicone rubber mold design lies in collaboration with experienced LSR companies. These specialized manufacturers have in-depth knowledge of LSR materials, molding processes, and mold design principles.

Click lsr company.

LSR companies work closely with designers to select the most suitable silicone material for specific applications, considering factors such as temperature resistance, chemical compatibility, and mechanical properties. They also provide valuable insights into optimizing part designs for manufacturability and cost-effectiveness.

Furthermore, LSR companies offer comprehensive services including prototyping, tooling fabrication, production molding, and quality assurance. Their expertise ensures that the final molded parts meet or exceed customer expectations in terms of functionality and performance.

In Conclusion

Liquid silicone rubber mold design plays a crucial role in achieving high-quality molded parts with precision and efficiency. By partnering with innovative companies like JVTECH and leveraging the expertise of experienced LSR manufacturers, businesses can unlock numerous benefits such as reduced time-to-market, improved product performance, and cost optimization. Embracing liquid silicone rubber mold design is a step towards staying competitive in today’s rapidly evolving manufacturing landscape.