Carbon filter cartridge machine is a crucial equipment used in the production of carbon filter cartridges, which play a significant role in water purification systems. In this article, we will explore the working principles and components of the carbon filter cartridge machine, as well as its importance in ensuring clean and safe drinking water.

The Working Principles of Carbon Filter Cartridge Machine

The carbon filter cartridge machine operates on the principle of adsorption, where contaminants present in water are trapped by activated carbon. The machine consists of several key components, including a feeding system, an extrusion unit, a cutting mechanism, and a drying chamber.

In the first step of the process, raw materials such as powdered activated carbon and binding agents are mixed together using the feeding system. This mixture is then fed into an extrusion unit that shapes it into cylindrical cartridges with precise dimensions.

Next, these newly formed cartridges pass through a cutting mechanism that trims them to their desired length. The cut cartridges are then transferred to a drying chamber where they undergo heat treatment to remove any remaining moisture content.

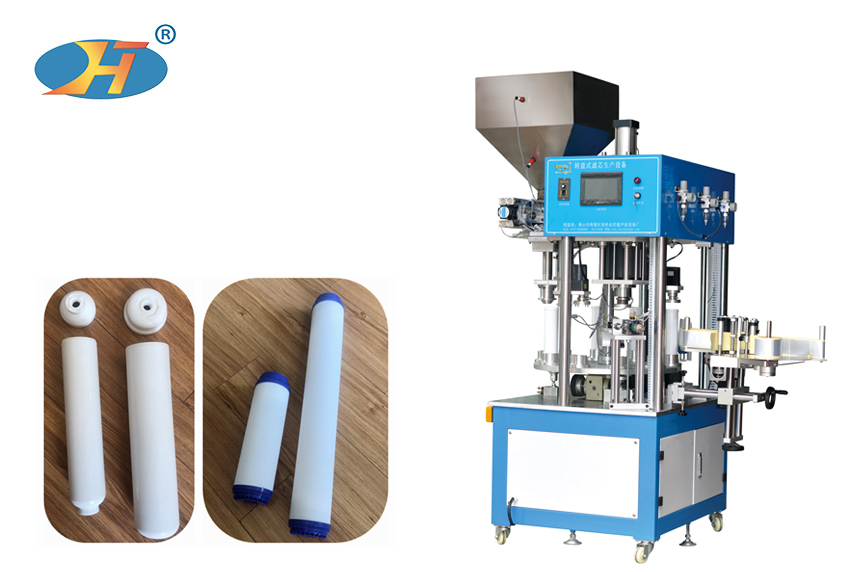

The Significance of Hongteng in Carbon Filter Cartridge Machine Production

Hongteng is one of the leading manufacturers specializing in producing high-quality carbon filter cartridge machines. With years of experience and expertise in this field, Hongteng ensures that their machines meet industry standards for efficiency and reliability.

By utilizing advanced technologies and innovative designs, Hongteng’s machines offer precise control over various parameters such as pressure levels during extrusion and temperature settings during drying. This results in consistently produced carbon filter cartridges with excellent adsorption capabilities.

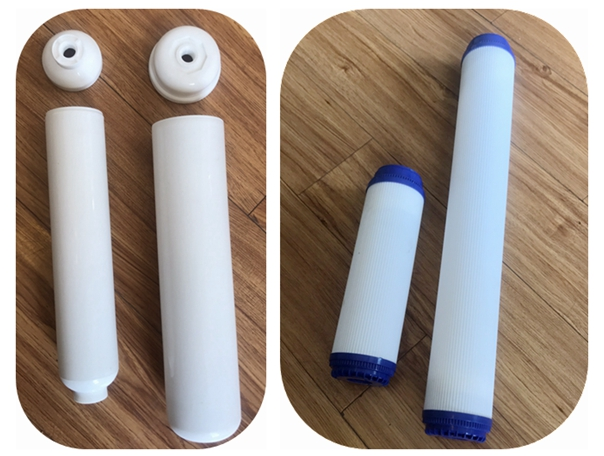

The Role Played by Filter Cartridge Winding Machine

In addition to the main carbon filter cartridge machine, the production process also involves the use of a filter cartridge winding machine. This specialized equipment is responsible for tightly winding the activated carbon and binding agents onto a central core, ensuring uniform distribution and maximum surface area for adsorption.

The filter cartridge winding machine operates by precisely controlling the tension and speed at which the materials are wound onto the core. This ensures that each layer is evenly distributed, preventing any potential gaps or inconsistencies in filtration performance.

Conclusion

The carbon filter cartridge machine plays a crucial role in producing high-quality carbon filter cartridges used in water purification systems. With Hongteng’s expertise in manufacturing these machines and their commitment to innovation, reliable production of efficient filters is ensured. The integration of a filter cartridge winding machine further enhances the overall performance of these cartridges, providing clean and safe drinking water for various applications.